Quartz glass fiber refers to a specialty glass fiber with a silica content exceeding 99.9% and a fiber diameter ranging from 1 to 15 μm. It possesses high heat resistance, capable of long-term operation below 1050°C and transient high-temperature resistance up to 1700°C.

Quartz glass fiber also boasts excellent electrical insulation properties, with the highest dielectric constant and dielectric loss coefficient of all mineral fibers. Therefore, quartz glass fiber is widely used in aviation, aerospace, military, semiconductors, high-temperature insulation, and high-temperature filtration.

Quartz fiber processing technology:

Quartz glass fiber production process: Quartz glass fiber is generally drawn from fused quartz glass rods extracted from pure natural crystals. The fiber purity is >99.99% SiO2. During the drawing process, heating methods include oxyhydrogen flame and plasma.

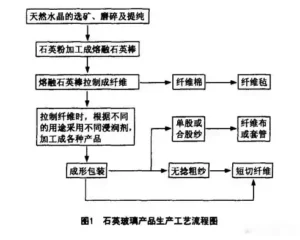

Depending on the intended use, a sizing agent is applied. Quartz glass fiber products include direct untwisted roving, twisted yarn (including single and plied yarns), fiber cloth, fiber sleeves, chopped strands, fiber cotton, fiber mat, and fiber bricks. The production process for various quartz glass fiber products is as follows:

First, the raw crystal or pure silica powder is placed in a vacuum pressure resistance furnace, melted and drawn into thin rods (about 2mm in diameter). When drawing, a layer of wetting agent is first applied to the quartz fiber, and then placed in an electric heating or hydrogen-oxygen flame environment for drawing.

In this way, a single-filament raw wire with a diameter of about 8μm can be obtained. Finally, the fiber raw wire is combined and twisted to obtain fiber yarn or fiber fabric.

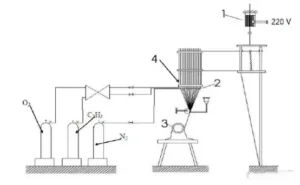

Schematic diagram of quartz fiber production equipment using the rod drawing method (gas heating): 1-rod feeder; 2-gas heating combustion device; 3-drawing machine; 4-quartz rod

The fibers drawn by the wire drawing machine have high strength, but poor corrosion resistance. Once exposed to the air, they may be corroded in a very short time. In the actual process, it is necessary to apply a wetting agent to the fiber surface during the fiber drawing process to inhibit fiber breakage and flying fibers, thereby helping to ensure the normal progress of the wire drawing operation.

Characteristics of quartz glass fiber

Quartz fiber should contain at least 99.9% silica, and its diameter generally ranges from one to several dozen microns. It exhibits high heat resistance, high-temperature and high-frequency electrical insulation, ablation resistance, thermal shock resistance, and excellent chemical stability. It can operate for extended periods below 1050°C and withstand transient high temperatures of up to 1700°C.

Its tensile strength is three times that of ordinary fibers. Furthermore, its dielectric constant at 1MHz is 3.70, and its dielectric loss factor is less than 0.001. At high frequencies and temperatures below 700°C, it retains over 70% of its strength.