Carbon fiber is primarily composed of carbon and possesses properties such as high temperature resistance, anti-friction, thermal conductivity, and corrosion resistance. It is fibrous, soft, and can be processed into various fabrics. Because its graphite microcrystal structure is preferentially oriented along the fiber axis, it has high strength and modulus along the fiber axis. Carbon fiber has a low density, resulting in high specific strength and specific modulus.

1. Cutting

The prepreg is taken out from the cold storage at minus 18 degrees Celsius, and after being awakened, it is first accurately cut according to the material pattern on the automatic cutting machine.

2. Paving

The second step is to lay the prepreg on the laying tooling, laying different layers according to the design requirements. All processes are carried out under laser positioning.

3. Molding

Through automated handling robots, preforms are delivered to the molding machine for compression molding (PCM). Walt can currently achieve molding within 5 to 10 minutes and has 800 to 1,000 t presses that can mold various large workpieces.

4. Cutting

After forming, the workpiece is sent to the cutting robot workstation for the fourth step of cutting and deburring to ensure the dimensional accuracy of the workpiece. This process can also be operated on the CNC.

5. Cleaning

The fifth step is to perform dry ice cleaning at the cleaning station to remove the release agent to facilitate the subsequent gluing process.

6. Glue application

The sixth step is to apply structural adhesive at the gluing robot station. The gluing position, gluing speed, and glue output are all precisely adjusted. Some connections with metal parts are riveted at the riveting station.

7. Assembly inspection

After applying glue, the inner and outer panels are assembled, and blue light inspection is carried out after the glue is cured to ensure the dimensional accuracy of key holes, points, lines and surfaces.

Carbon fiber is difficult to process

Carbon fiber combines the two major characteristics of strong tensile strength of carbon materials and softness and processability. Carbon fiber is a new material with excellent mechanical properties.

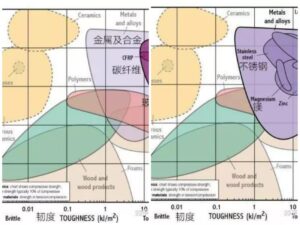

The strength of carbon fiber CFRP is significantly higher than that of glass fiber GFRP. The strength of carbon fiber is around 400 to 800 MPa, while the strength of ordinary steel is 200 to 500 MPa. In terms of toughness, carbon fiber and steel are basically similar, with no obvious difference.