The heat resistance of quartz fiber is determined by the inherent heat resistance of silicon dioxide. The softening temperature of quartz fiber is 1700°C, and typical quartz fiber can be used for long periods of time at 600-1050°C. When the temperature exceeds 1600°C, quartz fiber begins to sublimate.

This is an endothermic reaction that consumes heat energy, so quartz fiber can also be used as an ablative material. Utilizing this property, quartz glass fiber is used as an ablative material for re-entry into the atmosphere of spacecraft and intercontinental missiles. Furthermore, at high temperatures, quartz fiber does not shrink like high-silica fiber. After being heated at 1000°C for 1000 hours, the loss of quartz glass fiber will not exceed 1.5%.

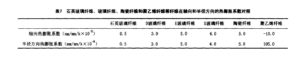

The following table is a comparison of the thermal expansion coefficients of quartz fiber, glass fiber, ceramic fiber and polyethylene fiber in the axial and radial directions. It can be seen from the table that the thermal expansion coefficient of quartz glass fiber is the lowest among all mineral fibers and is consistent in all directions. Unlike organic fibers, there is a large gap between the axial and radial directions, thus ensuring the quality of the composite material.

Quartz fiber can be used in the following areas:

1. Heat-resistant auxiliary equipment around spacecraft engines, including fire-resistant cables, insulation walls, and fire shields.

2. Fire protection systems for spacecraft launch pads.

3. Thermal insulation for spacecraft propulsion systems.

4. Ablation materials for spacecraft re-entry.

5. Fire protection for spacecraft during takeoff.

6. Fire protection for spacecraft fuselages.

7. Thermal insulation for missile and rocket propulsion systems.

8. Asbestos and ceramic fiber substitutes.

9. Thermal insulation materials in the semiconductor industry.

10. Thermal insulation for high-temperature exhaust pipes in automobile and heavy truck transmissions.

11. Protective covers for fuses.

12. Thermal insulation for optical fiber drawing.

13. Filter materials for hot gases.

14. Protective covers for thermocouples.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.