Continuous Nickel-Plating Process for Carbon Fibers and Their Shielding Composite Materials

Abstract:To enhance the production efficiency of the nickel-plating process for carbon fibers and to develop filled composite electromagnetic interference (EMI) shielding materials, nickel-plated carbon fibers (Ni-CF) were produced using a self-developed continuous electroplating production equipment.

Subsequently, nickel-plated carbon fiber reinforced acrylonitrile-butadiene-styrene copolymer (ABS) composites (Ni-CF/ABS) were prepared. The influence of a coupling agent on the mechanical properties of the composites, as well as the effects of fiber metallization and fiber content on the EMI shielding properties, were investigated. The results indicated that the coupling agent improved the mechanical properties of the composite, with tensile and flexural strengths reaching 41 MPa and 61.4 MPa, respectively.

The composite achieved optimal electromagnetic shielding effectiveness when the fiber mass fraction was 12%.

Introduction

With the advancement of science and technology and the rapid growth of urban populations, a large number of devices such as automobiles, electronics, communication equipment, computers, and electrical appliances have entered households.

The increasing prevalence of electronic and electrical facilities in production and daily life has led to electromagnetic wave radiation growing at an annual rate of 7% to 14%. Consequently, electromagnetic interference (EMI) problems caused by electromagnetic waves are becoming increasingly severe.

Therefore, finding ways to reduce electromagnetic radiation intensity, prevent electromagnetic radiation pollution, protect the environment, and safeguard human health has become an urgent item on the agenda.

The research and development of electromagnetic shielding materials has become a significant topic of public concern. Metallic materials are ideal for shielding against electromagnetic wave radiation and are currently the most widely used EMI shielding materials.

Research on new EMI shielding materials is moving towards higher shielding efficiency and lower density. The trend in modern materials development involves replacing large amounts of metal with plastics.

Carbon fibers possess high strength, low weight, and relatively high electrical conductivity, making them suitable for preparing lightweight shielding materials directly. However, their conductivity is inferior to that of corresponding metallic materials.

Metal-plated carbon fibers not only retain the high strength of carbon fibers but also exhibit metal-like conductivity, making them ideal additives for modern high-performance shielding materials.

Our research group previously prepared Ni-CF/ABS EMI shielding materials using a solution mixing method, achieving a shielding effectiveness of up to 83 dB in the frequency range of 30–1200 MHz.

However, the solution mixing process is cumbersome, limited to laboratory research, and difficult to apply in practical production. This paper investigates the preparation of Ni-CF/ABS EMI shielding composites using a single-screw extrusion process connected to automatic pelletizing equipment.

This preparation method offers lower cost and enables large-scale automated production, potentially filling the domestic gap for carbon fiber composite materials with simple processes, moderate cost, and excellent EMI shielding performance.

In this study, the authors first metallized the surface of carbon fibers and then prepared Ni-CF/ABS composites using the single-screw extrusion process. Factors influencing the mechanical properties and EMI shielding performance of the composites were studied to provide a basis for designing high-performance carbon fiber EMI shielding materials.

The experimental results show that Ni-CF/ABS composites possess excellent mechanical properties and outstanding EMI shielding performance, indicating promising prospects as EMI shielding materials.

Experimental Section

1.1 Raw Materials

The carbon fibers used were T300 type with a density of 1.75 g/cm³, a diameter of 6–8 μm, and each tow containing 12,000 filaments. Reagents for electroplating were of analytical grade.

1.2 Electroplating and Surface Treatment of Carbon Fibers

Chemical reagents including nickel sulfate and boric acid were proportionally mixed to prepare the plating solution. Carbon fibers were electroplated with nickel at an appropriate temperature.

The resulting nickel-plated carbon fibers (Ni-CF) were repeatedly rinsed with copious amounts of clean water, dried, and then subjected to surface treatment. Subsequently, the Ni-CF were immersed in a mixed solution for 30 minutes and then dried.

1.3 Composite Preparation

Various additives were thoroughly mixed with ABS resin in specific proportions. The single-screw extrusion method was employed to coat the Ni-CF with the mixed ABS. In this process, the mixed ABS pellets were fed from the main hopper, and the Ni-CF were fed from a side feeder.

The extrusion temperature ranged from 220 to 260°C. The coated material exiting the die was cut into pellets of appropriate length, which were then injection-molded into standard test specimens. The mass fractions of carbon fibers (Wf) in the composites were 9%, 12%, and 15%, respectively. The thickness of the composite samples was 2 mm.

1.4 Performance Testing

The morphology of carbon fibers before and after plating was observed using Scanning Electron Microscopy (SEM). The coating thickness was observed using an optical microscope.

Flexural properties were tested according to GB/T 9341-2000 using a CSS-44001 electronic universal testing machine.

Electromagnetic shielding effectiveness (SE) was measured according to QJ2809-96 by the National Institute of Metrology, China. Testing conditions: temperature 22.5°C; humidity 45% (RH); test frequency range 30–1200 MHz.

Results and Analysis

2.1 Study on the Continuous Nickel-Plating Production Process for Carbon Fibers

This study first involved surface nickel-plating of carbon fibers using a self-developed continuous electroplating production line.

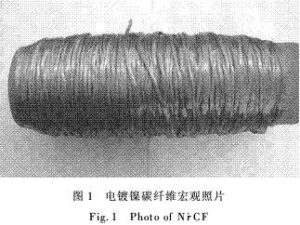

Figure 1 shows a macroscopic photograph of the collected plated carbon fibers. It can be seen that the surface of the nickel-plated carbon fibers appears silvery-white with a metallic luster.

A schematic diagram of the electroplating production equipment is shown in Figure 2.

2.2 Morphology of Carbon Fibers Before and After Plating

Figure 3 shows SEM images of carbon fibers before and after plating. Comparing Figures 3(a) and 3(b), it is evident that the nickel coating on the plated carbon fibers is uniform and continuous.

Furthermore, the surface of the nickel layer is rough, which is beneficial for improving the interfacial bonding between the carbon fibers and the ABS matrix. Figure 4 shows an optical micrograph of the cross-section of a mounted Ni-CF sample. The coating thickness is uniform, and calibration measurements indicate a thickness of approximately 1.5 μm.

2.3 Influence of Surface Treatment on Mechanical Properties

The interface is a crucial component of composites, acting as a bridge connecting the reinforcement and the matrix. It serves as the link for transferring external loads from the matrix to the reinforcement and plays an extremely important role in the macroscopic properties of the composite.

Titanate is a commonly used and effective coupling agent and surface treatment agent that can improve the interfacial bonding strength between fibers and matrix, thereby optimizing the macroscopic properties of the composite. Therefore, this experiment used titanate as a coupling agent for fiber surface treatment and compared the mechanical properties of composites with and without the coupling agent.

Figure 5(a) shows the tensile strength and tensile modulus of composites made from unplated carbon fibers (CF), nickel-plated carbon fibers without coupling agent (Ni-CF), and nickel-plated carbon fibers treated with titanate coupling agent (Ni-CF-T), all compounded with ABS (abbreviated as CF/ABS, Ni-CF/ABS, and Ni-CF-T/ABS, respectively, with a fiber mass fraction of 12%).

Figure 5(a) indicates that Ni-CF-T/ABS treated with the titanate coupling agent exhibited the highest tensile strength and tensile modulus, at 41 MPa and 7 GPa, respectively. The tensile strengths of CF/ABS and Ni-CF/ABS were similar, around 27 MPa, while their tensile moduli were 6 GPa and 6.5 GPa, respectively. The tensile properties of Ni-CF/ABS were slightly higher than those of CF/ABS.

Figure 5(b) shows the flexural strength and flexural modulus of CF/ABS, Ni-CF/ABS, and Ni-CF-T/ABS. It can be seen from Figure 5(b) that Ni-CF-T/ABS possesses the highest flexural strength and flexural modulus, at 61.4 MPa and 4.8 GPa, respectively. CF/ABS has the lowest flexural strength and modulus, at 45 MPa and 3.2 GPa, respectively. Ni-CF/ABS falls between the two, with values of 54.6 MPa and 4 GPa.

From the above tensile and flexural test results, it is clear that the carbon fiber/ABS composite has the lowest mechanical properties, the nickel-plated carbon fiber composite is intermediate, and the titanate-treated nickel-plated carbon fiber composite exhibits the highest mechanical properties.

Its tensile and flexural strengths increased by 52% and 12.5%, respectively, compared to the untreated version. The possible reasons are as follows: Firstly, due to the small diameter of individual carbon fibers, significant electrostatic adhesion exists between them, affecting fiber dispersion during the injection molding process and resulting in lower overall mechanical properties for the carbon fiber composite.

For nickel-plated carbon fibers, the metal coating on each filament reduces the electrostatic adhesion within the tow. Under the same injection molding conditions, the dispersion of nickel-plated carbon fibers is significantly better than that of unplated fibers.

Secondly, equipment like the single-screw extruder causes some damage to the fibers during composite preparation, affecting their strength. The nickel coating provides a protective layer, mitigating fiber damage; thus, the mechanical properties of the nickel-plated carbon fiber composite are superior to those of the unplated carbon fiber composite.

The titanate coupling agent acts as a fiber surface treatment agent. Coupling treatment aids in fiber dispersion within the matrix and improves the uniformity and interfacial bonding of the composite, giving it the highest mechanical properties. Therefore, in subsequent studies, the titanate coupling agent was used to treat the nickel-plated carbon fibers.

2.4 Influence of Fiber Metallization on Electromagnetic Shielding Performance

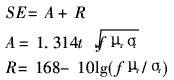

According to Schelkunoff’s electromagnetic shielding theory, the total shielding effectiveness (SE) of a material is composed of absorption loss (A), reflection loss (R), and multiple reflection loss (B). When A is greater than 10 dB, B can be neglected, and the SE is the sum of A and R, expressed by the formula:

`SE = A + R = 50 + 10 log10(ρf)⁻¹ + 1.7t√(fμrσr)`

Where: μr is the relative permeability of the material compared to copper; σr is the relative conductivity of the material compared to copper; f is the frequency of the electromagnetic wave; t is the material thickness.

Therefore, when the material thickness (t) and incident wave frequency (f) are constant, the SE of the material primarily depends on σr and μr. After fiber surface metallization, the values of σr and μr increase, leading to enhanced SE of the composite.

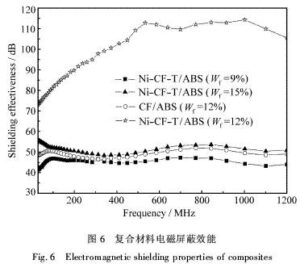

Figure 6 shows the EMI SE curves of the composites in the 30–1200 MHz frequency range. From Figure 6, it can be seen that when Wf = 12%, the SE of CF/ABS is around 50 dB, while that of Ni-CF-T/ABS is above 73 dB, reaching a maximum of 114 dB. In the range of 500–1000 MHz, the enhancement of EMI SE due to nickel plating is particularly significant, with an increase of up to 60 dB. Clearly, fiber surface metallization can markedly improve the EMI shielding performance of the material. Furthermore, the SE of 110 dB exceeds that of similar foreign products.

2.5 Influence of Fiber Content on Electromagnetic Shielding Performance

Fiber content not only affects the mechanical properties of the composite but also significantly influences its electrical conductivity and EMI shielding performance.

To reduce the cost of the composite, it is important to minimize carbon fiber usage while meeting EMI SE requirements. Therefore, studying the effect of carbon fiber content on the EMI SE of the composite is of great significance. As shown in Figure 6, when the fiber mass fraction is 9%, the SE of the composite ranges from 40 to 50 dB. At a 15% mass fraction, the SE ranges from 50 to 60 dB. However, at a 12% mass fraction, the SE remains above 73 dB, reaching a maximum of 114 dB.

The shielding performance of the material is influenced by factors such as fiber content and fiber dispersion. Higher fiber content generally leads to better electrical conductivity and higher shielding performance. However, when the fiber content exceeds a certain threshold, it becomes difficult to achieve uniform dispersion within the matrix. Poor dispersion can degrade the electrical conductivity of the material, thereby reducing its EMI shielding performance.

Under the existing experimental equipment and molding conditions, dispersion becomes difficult when the fiber mass fraction exceeds 12%. Consequently, the composite achieves its highest shielding performance at a fiber mass fraction of 12%.

Conclusions

(1) A continuous nickel-plating production line for carbon fibers was successfully developed. The nickel-plated carbon fibers produced by this line exhibit a continuous, uniform, and controllable coating thickness.

(2) The tensile and flexural properties of the composite prepared with fibers treated by the titanate coupling agent were significantly improved. Tensile and flexural strengths reached 41 MPa and 61.4 MPa, representing increases of 52% and 12.5%, respectively, compared to the untreated composite.

(3) Fiber surface metallization enhances the EMI shielding performance of fiber-reinforced ABS composites. The EMI SE of the composite is highest in the frequency range of 500–1000 MHz.

(4) Fiber content has a significant impact on the shielding performance of the composite. The composite exhibits optimal EMI shielding effectiveness when the fiber mass fraction is 12%.