BN-PA Recycled Carbon Fiber Chopped Particles(Special for Nylon Resin Reinforcement)Technical Data Sheet

Characteristics

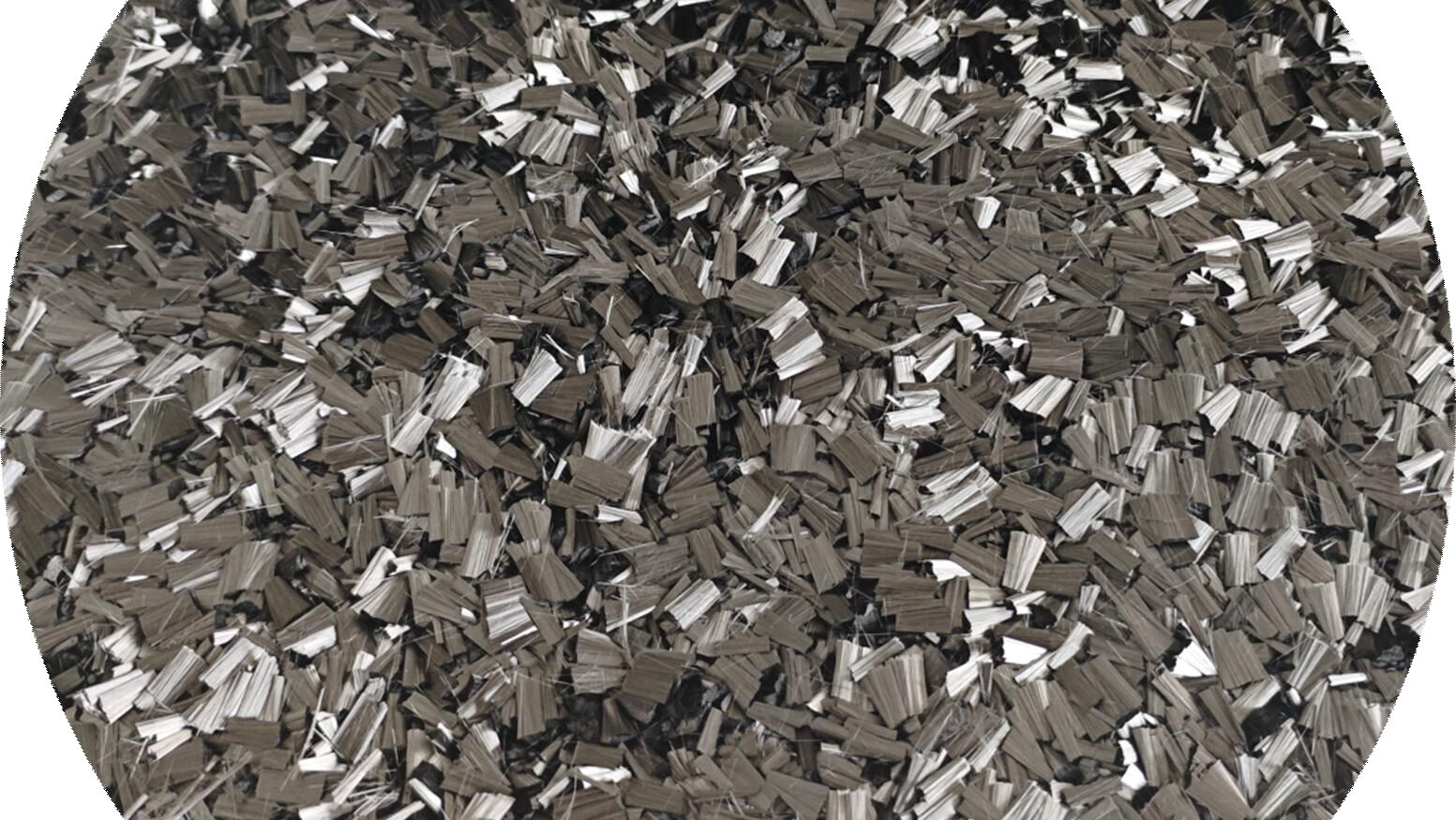

BN-PA Recycled chopped carbon fiber,in the state of clustered particles,is a product made of recycled PAN-based carbon fibers recovered and extracted from CFRP waste carbon planks and scraps,and are produced by cutting,sizing particle forming and so The product features that: during extrusion processing and production. ( Recycled Carbon Fiber Chopped Particles )

It is mainly mixed with PA6,PA66 and other nylon resins to make reinforcement particles for use.BN-PA reinforced nylon composites can have the following characteristics:Significantly improve the strength and elastic modulus of products;Excellent wear resistance,fatigue resistance,creep resistance and dimensional stability;Light weight,good electrical conductivity and thermal conductivity.

The sizing agent used in BN-PA products has good nylon resin compatibility to promote the excellent interface property. The product features that:

- High interfacial bonding strength with nylon resin;

- Excellent dispersivity in nylon resin;

- The product is in the state of clustered particles,with high packing density,which makes it easier and smootherto feed

Performance parameters

| Characteristicitem | Inspectionstandards | Referencevalue |

| Fibertype | BN-PA | |

| Appearance | Visualinspectionmethod | Blackgranule |

| Tensilestrength | 3800MPa/4500MPa/4900MPa | |

| Fiberdensity | GB/T30019-2013 | 1.78~1.80g/cm³ |

| Fiberdiameters | 5-7μm | |

| Fiberlength | 6mm±0.5mm | |

| Bulkdensity | ISO1510:2000 | 400~460g/L |

| Sizingagenttype | Compositionbaseonpolyamide | |

| Sizingagentcontent | GB/T26752-2011 | 2.0%~5.0% |

| Moisturecontent | GB/T9914.1-2013 | ≤0.5% |

| Resistivity | 10月3日 | |

| OptimumapplicationresinsPA66,PA6andothernylonresins | ||

| Otherapplicationresins | PC,ABS,POM,PBT,PET,etc. | |

Storage ( Recycled Carbon Fiber Chopped Particles )

- Please store the product in a dry environment,with temperature and humidity recommended to be controlled between 0- 30℃and below 50%.

- This product should always be placed under sealed packaging before use.

Note:

Factors such as humidity and temperature during use and transportation can affect product performance.

*Standard package 20kg;Dimensions:510mm*320mm*365mm;Bag size:1000mm*600mm;Pallet sizes:1100mm*1100mm.

The product holds GRS and SGS certification.Data and parameters quoted in this data sheet were obained from this material under strict control in Saxobran Laboratory.Therefore these data and parameters can reflect the representative attributes of the product. Saxobran does not assume any responsibility if the user improperly uses these producis.The numerical value obtained by applying this material comes from the processing details.Users are advised to develop their own application technology and obtain data consistent with their specific applications and processes.

Cautions for Saxobrantech product use

Due to the conductivity of carbon fiber,various electronic and electrical equipment on site need to be protected against dust in order to prevent power accidents.

Carbon fiber or its products on the skin may cause itching,pain,inflammation and other symptoms.In order to protect respiratory organseyes and skin,please use corresponding labor protection articles.

For other instructions,the material safety data sheets MSDS Jare available.Please ask Saxobrantech business department for them.

Notes

The product applications listed here are only the application examples. Saxobrantech does not guarantee its applicability and safety.

When using the product,please confirm its safety and relevant restrictions according to its purpose.

Customers are advised to investigate the end use of their products in advance to ensure the correct use of Saxobrantech products.In order to ensure that the Saxobrantech products are not misused,it is recommended to contact the business representative of Saxobrantech business representative.

Saxobran Co.,Ltd.

Address:219A,Comprehensive Bonded Zone,255000 Zibo City,Shandong Province,P.R.China . E-mail:sales@saxobran.cn