Hydrogen Energy Perspective

A Brief Analysis of Carbon Fiber Product Classification—Carbon Paper, Carbon Cloth, Carbon Felt

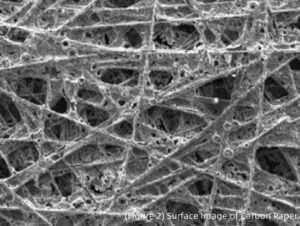

Carbon paper, as the name implies, refers to carbon fiber paper. However, in the current practical applications of the hydrogen energy industry, “carbon paper” generally refers to “finished carbon fiber paper obtained through post-processing.”

The post-processing typically includes impregnation and compounding, curing and reinforcement, carbonization and graphitization, hydrophobic modification, and microporous layer preparation.

“Carbon paper” does not specifically refer to a single item but rather a series of products. Their commonality lies in being paper-like products primarily made from carbon fiber, supplemented with dispersants, binders, and reinforcing agents, and produced via wet or dry papermaking processes. In the papermaking industry, carbon paper can be classified as specialty paper.

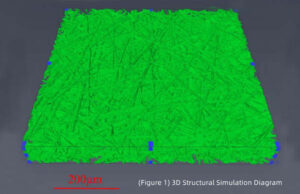

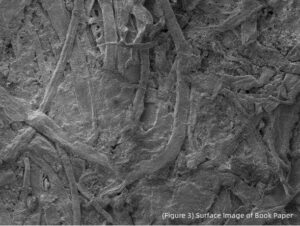

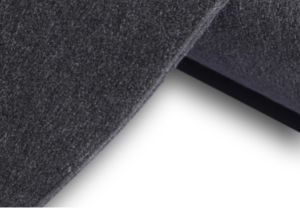

Unlike common book paper, carbon paper, due to its specific applications (gas diffusion, mass and heat transfer, mechanical support, etc.), features a rougher surface and more unique hydrophilic/hydrophobic and pore structure designs, as shown in Figures 1 and 2.

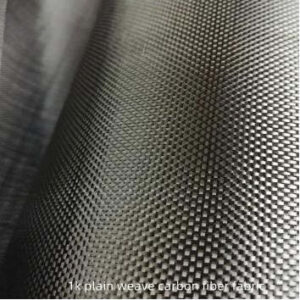

Carbon cloth, as the name suggests, is carbon fiber fabric—a woven material made from carbon fibers. It not only retains the intrinsic properties of carbon materials but also possesses the flexibility and processability of textile fibers.

With high specific strength, strong bending resistance, and excellent creep resistance, it is widely used in industries such as national defense and military, sports and entertainment, industrial construction, and batteries. Similar to carbon paper, carbon cloth is also a general term for a series of products.

Variations in fiber raw materials, weaving methods, and application fields have led to diverse carbon cloth products.

Carbon felt, also known as carbon fiber felt, is a type of non-woven carbon fiber fabric. It is typically formed through dry forming processes (such as airlaid web-forming) and then consolidated via thermal bonding, needle punching, or hydroentangling to produce the finished carbon felt.

Carbon felt can be converted into graphite felt through high-temperature heat treatment. Both carbon felt and graphite felt are widely used as thermal insulation materials. Their excellent corrosion resistance and adsorption properties make them suitable for filtration and corrosion protection materials. Additionally, they are extensively used as electrode materials in flow batteries.

Carbon paper, carbon cloth, and carbon felt can all serve as base materials for fuel cell gas diffusion layers, applicable in PEM fuel cells, PEM electrolyzers, flow batteries, and more. At the same time, their related products hold significant market potential in fields such as thermal insulation, composite reinforcement, and filtration and adsorption.