Aramid fiber, short for polyphenylene phthalate, is considered one of the world’s three highest-performance fibers, along with carbon fiber and ultra-high molecular weight polyethylene fiber. Its low relative density, high strength, high modulus, high-temperature and corrosion resistance, and excellent insulation properties make it widely used in military, aerospace, electronics, transportation, construction, and healthcare applications.

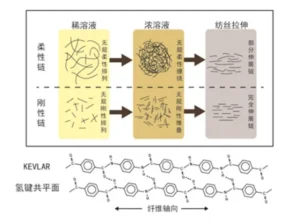

Figure 1 Aramid fiber

Aramid fiber is a synthetic aromatic polyamide fiber, a fiber made of a synthetic linear polymer composed of aromatic rings connected by amide bonds. The main chain is composed of aromatic rings and amide bonds.

The aromatic ring structure has high rigidity, and the polymer chain is in an extended state to form a rod-like structure. At the same time, the linear molecular chain structure makes the aramid fiber have high space utilization, so it can accommodate more polymers per unit volume, so the strength is higher.

Figure 2 Schematic diagram of flexible segment polymers and rigid segment polymers

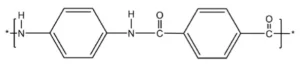

The main molecular chain of para-aramid is a linear structure composed of alternating amide bonds and benzene rings. The amide bonds and benzene ring groups form a conjugated structure, which makes internal rotation difficult, resulting in a rigid structure that determines the high strength of aramid fibers.

The macromolecular chains form a cross-linked network structure through hydrogen bonds. The main molecular chain arrangement is regular, highly oriented along the fiber axis, and has high crystallinity. During the spinning process, the chain structure can be extended to achieve a high modulus.

Figure 3 PPTA

The macromolecules in meta-aramid are arranged in a zigzag pattern, giving the meta-aramid molecular chain flexibility and a high glass transition temperature. This results in excellent high-temperature resistance, flame retardancy, and insulation properties.

This high-performance, high-temperature specialty fiber also boasts excellent thermal stability, maintaining over ten years at 220°C and 65% of its mechanical strength after 1000 hours at 240°C. It only releases small amounts of gas at temperatures above 370°C. It is flame-retardant, and its surface carbonizes during high-temperature combustion, without supporting combustion or producing droplets.

2. Aramid preparation method

2.1 Preparation method of para-aramid PPTA

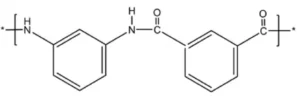

The low-temperature solution polycondensation method for synthesizing PPTA polymer is currently the most mature process in the world. The preparation method of PPTA fiber is as follows: first, paraphenylenediamine (PPDA) and terephthaloyl chloride (TPC) are polycondensed through a low-temperature solution to obtain PPTA polymer, and then this polymer is dissolved in concentrated sulfuric acid and spun into PPTA fiber using a dry-jet wet spinning method.

Figure 5 PPTA preparation process

2.2 Preparation method of meta-aramid PMIA

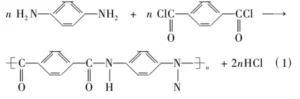

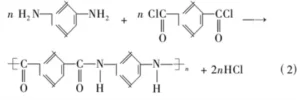

PMIA is synthesized by the low-temperature polycondensation of isophthaloyl chloride and m-phenylenediamine. Meta-aramid can be produced by dry spinning, wet spinning, or dry-jet-wet spinning. The reaction equation for PMIA is shown below.

Figure 6 PMIA preparation process

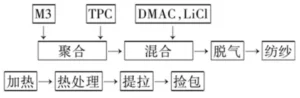

2.3 Preparation of Aramid III Resin

Aramid III resin is a ternary copolymer obtained by introducing a third unit (M3) into the polycondensation reaction, partially replacing PPDA and TPC in the polycondensation reaction in a low-temperature solution. In this polymerization reaction, a strong polar solvent N, N-dimethylacetamide (DMAC) and a co-solvent lithium oxide (LiCl) need to be added. The production process flow is shown in the figure below.

Figure 7 Aramid III production process flow