What is the difference between aramid fiber and carbon fiber?

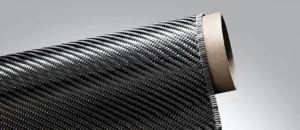

1. Color

Aramid fiber is a bright golden yellow in its natural state, while carbon fiber is always black and cannot be colored. If you need to change the appearance of carbon fiber, you can only mix it with other materials.

2. Weaving

Common weaves for aramid fibers are plain and twill. (See the image below.) Twill weave offers greater flexibility, while plain weave is more uniform and offers greater stability.

Carbon fiber fabrics are woven according to the direction of their fibers, and are commonly found in two weave styles: plain and twill. Plain weave is more resistant to cutting, while twill weave has straighter, longer strands, and is more flexible and stronger than plain weave.

3. Units of measurement

Aramid fiber uses “Denier” as a unit of measurement for fiber density, symbolized by D. A larger D indicates a thicker yarn. Common aramid fibers come in two grades: 600D and 1500D. Compared to 1500D aramid fiber, 600D aramid fiber is more difficult to produce, more scarce, and more expensive, but the resulting product is lighter, more refined, and has a better feel.

Carbon fiber is denoted by the number of fibers (K). Carbon fiber cloth is woven from bundles of carbon fiber filaments. 1K means a bundle contains 1,000 fibers, while 3K means a bundle contains 3,000 fibers.

Do aramid fiber and carbon fiber have any impact on electronic products?

The use of aramid fiber and carbon fiber has become common in many electronic products, so what impact do they have on electronic products?

1. Tensile strength

Tensile strength is the maximum stress a material can withstand when stretched apart before breaking. Some non-brittle materials deform before breaking, but aramid and carbon fibers are brittle, so they break without deforming.

2. Conductivity

Aramid fiber is an excellent insulator, with a dielectric strength of up to 20 kV/mm. Carbon fiber, on the other hand, is a very good conductor of electricity. Its conductive properties absorb, reflect, and even counteract electromagnetic waves emitted by mobile phones. A carbon fiber phone case can reduce signal strength by an average of 40%-60%.

If the product requires high strength, then the stronger the aramid fiber, the better. However, if the product requires high rigidity, then carbon fiber is a better choice.