Basalt is a volcanic extrusive rock and one of the most widely existing and distributed minerals on Earth. The continuous fiber produced from it represents a qualitative leap in fiber quality compared to ordinary rock wool.

Its high elastic modulus, high thermal stability, and excellent acid and alkali resistance have led to its widespread application. In recent years, the United States, South Korea, China, and Japan have successively initiated research in this field, with the United States achieving a production scale of 1000–1500 tons per year.

1. Technical Advantages of Basalt Fiber

Compared to fiber materials such as glass fiber and mineral wool fiber, basalt fiber possesses the following superiorities:

1.1 Good Tensile Strength and Reinforcement Effect

Basalt fiber can retain its strength for 1200 hours under the action of water at 70°C, whereas ordinary glass fiber loses its strength in less than 200 hours. Its tensile strength can increase by 30% at temperatures of 100–250°C, while ordinary glass fiber decreases by 23%.

Single-fiber pull-out tests indicate that the bonding ability of basalt fiber with epoxy polymers is higher than that of glass fiber and can be further improved after treatment with silane coupling agents. Therefore, basalt fiber can replace asbestos, which is slated for prohibition, as a reinforcing material for high-temperature structural composites, rubber technical products, etc., and can also be used as reinforcement for friction plates in components like brakes and clutches.

1.2 Excellent Corrosion Resistance and Chemical Stability

Basalt fiber exhibits unique chemical stability in alkaline solutions and has better acid resistance than ECR glass fiber, offering significant acid and alkali resistance at a much lower cost.

It can be applied in fiber-reinforced concrete structures and civil engineering materials. It holds broad application prospects, especially in building structures such as bridges, tunnels, dams, floor slabs, as well as asphalt concrete pavements and airport runways that are frequently exposed to high humidity, acids, alkalis, and salt media.

1.3 Good Insulation Properties

The dielectric loss tangent of basalt fiber is similar to that of glass fiber. Basalt fiber treated with specialized sizing agents has a dielectric loss tangent 50% lower than ordinary glass fiber.

It can be used to manufacture high-voltage (up to 250 kV) electrical insulation materials, low-voltage (500V) equipment, antenna radomes, radar radio equipment, etc. Basalt fiber treated with specialized sizing agents can also be used to produce new types of heat-resistant dielectric materials.

1.4 High-Temperature Resistance and Low-Temperature Thermal Stability

Its heat resistance is close to that of high-temperature quartz glass fiber. At 400°C, it retains 85% of its original breaking strength; at 600°C, it retains 80%. Under the same conditions, mineral wool retains only 50%–60% of its original strength, while glass wool is completely destroyed.

If basalt fiber is pre-treated at 780–820°C, it can operate at 860°C without shrinkage. Its strength remains unchanged after long-term exposure to low-temperature liquid nitrogen (-196°C), making it an effective low-temperature insulation material.

1.5 Excellent Elastic Modulus

The elastic modulus of basalt fiber is similar to that of expensive S-glass fiber, with comparable strength. It demonstrates good weaving performance for fabrics weighing 150–210 g/m². It can replace S-glass and other glass fibers in manufacturing insulation products and composites, hard armor, and various GFRP products.

For example, glass fiber pipes made with E-glass can withstand only 25 atmospheres of pressure with a maximum diameter of 2 meters, whereas pipes made with basalt fiber can withstand 60 atmospheres with diameters up to 3 meters.

1.6 Good Thermal and Acoustic Insulation Properties

Basalt fiber and its products possess excellent structural characteristics for thermal and acoustic insulation. Its sound absorption coefficient is even higher than that of E-glass, making it an efficient soundproofing material.

It can be used in public halls in the form of diluted felt or boards, and as thermal and acoustic insulation material in automotive and shipbuilding.

2. Preparation Methods for Basalt Fiber

Depending on the container used for melting the raw materials, production methods are divided into the crucible method and the tank furnace (direct melt) method. The former involves adding basalt batch materials to a crucible, melting at high temperature, clarifying, homogenizing, and then drawing the molten material through a bushing into fibers.

This method has low energy utilization, with the effective utilization rate of the crucible being only 10%–18%. The tank furnace drawing method, also known as the direct method, involves feeding prepared batch materials directly into the furnace. After high-temperature melting, clarification, and homogenization, the melt flows directly into the forming forehearth and is drawn into fibers through bushings. Compared to the crucible method, this process is simpler, more direct, and energy-efficient.

The preparation methods vary slightly for different fiber types. The manufacturing methods for basalt staple fiber, continuous fiber, and ultrafine fiber are briefly described below.

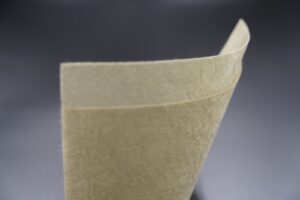

2.1 Basalt Staple Fiber

Basalt staple fiber is typically produced using the vertical air blowing process. The process is as follows: Raw materials are crushed into blocks about 50 mm in diameter and fed into a melting furnace.

Melting occurs at 1450–1500°C. The homogenized basalt melt is formed into a continuous stream of a certain diameter through a platinum-rhodium bushing and enters a spray head. In the fiber spray head, compressed air or superheated gas acts as the energy carrier, applying a blowing pressure (0.6–0.9 MPa) to the basalt melt stream; the velocity of the energy carrier approaches the speed of sound.

Under the action of the energy carrier flow, droplets of basalt melt are transformed into basalt staple fibers.

2.2 Continuous Basalt Fiber

The drawing process is as follows: Washed basalt blocks (50–60 mm) are melted in a tank furnace and drawn through a platinum-rhodium bushing, then wound onto a forming package (bobbin). Compared to glass melting, basalt melting tanks are smaller, no batching is required, and the production process is more concise.

Because basalt melt has lower thermal transparency than glass melt, is prone to crystallization, and has high viscosity in the drawing zone, special furnaces and equipment must be constructed. Stability of industrial parameters is ensured by incorporating components such as separation walls between the melting and working zones, riser channels, thermal barriers, thin-layer melt overflow zones, and chutes.

2.3 Ultrafine Basalt Fiber

Ultrafine basalt fiber is produced using the flame blowing process. The process is as follows: Ground and washed basalt fragments are fed into a tank furnace by a feeding mechanism.

Basalt melts under the action of a vertical mixture of fuel gas and air. The melt passes through a forehearth into a bushing, forming primary fibers below the bushing. These are guided by drawing rubber rollers to a nozzle. The high-temperature gas stream ejected from the nozzle scatters the primary fibers into staple ultrafine fibers with lengths of 20–200 mm.

These are then conveyed by a collection cylinder to forming equipment, settle onto the surface of a slowly rotating perforated drum, and after being rolled, form a felt on another collecting roller. When the felt reaches the required thickness, it is cut along its generatrix and removed.

The platinum-rhodium bushings used in this process weigh up to 2.5 kg, have relatively low stability, and require replacement after more than 3 months of use, resulting in high maintenance costs.

3. Basalt Fiber Product Types

3.1 Fiber-Reinforced High-Toughness Waterproof Crack-Resistant Tape

This is a basalt asphalt crack-sealing tape for repair, made from specially modified asphalt as the base material and high-performance composite basalt fiber as the reinforcement, produced through a high-temperature hot-melt cycle.

It offers advantages such as good self-adhesion, high tensile strength, low oil bleeding, high heat resistance, high-temperature dimensional stability, waterproofing, corrosion resistance, and convenient construction. It can improve interlayer bonding and watertightness in asphalt pavements, effectively prevent reflective cracking, water damage, and other distresses, extend the service life after road repair, and reduce maintenance costs.

It is suitable for new or renovated pavement/bridge deck paving structures, pavement pothole repair, sealing vertical joints at connections between old and new pavements, and seamless bridge expansion joints.

3.2 Basalt Fiber Cement Chopped Strand

This is a hydrophilic product formed by special surface treatment and chopping of continuous basalt fiber. Adding basalt fiber cement chopped strand increases the compressive strength of cement concrete by about 10%, flexural strength by 25%, and meets requirements for 300 freeze-thaw cycles.

It can improve the flexural and crack resistance of subgrade, pavement, and bridge deck concrete; enhance the strength of cement concrete precast components and reduce crack formation. It is suitable for incorporation into cement concrete pavements, bridge decks, and cement precast elements to improve crack resistance, flexural performance, etc.

3.3 Basalt Fiber Asphalt Chopped Strand

This is an oleophilic product formed by special surface treatment and chopping of continuous basalt fiber. Adding basalt fiber asphalt chopped strand can improve the fatigue cracking resistance of asphalt mixtures by more than 2 times compared to mixtures without it, increase low-temperature crack resistance by 15%–30%, and enhance rutting resistance by 25%–40.

Incorporating basalt fiber asphalt chopped strand into asphalt mixtures provides reinforcement, strengthening, toughening, and crack resistance, inhibits fatigue damage, reduces pavement distresses, postpones major, medium, and minor repairs, significantly extends the design service life of road pavements, and lowers maintenance costs.

It is suitable for upper, middle, and lower layers of asphalt concrete pavement structures such as AC, SMA, SUP, and PAC. In the upper layer, it reduces thermal shrinkage cracks and load-induced cracks; in the middle layer, it improves rutting resistance; in the lower layer, it enhances resistance to reflective cracking and rutting.

3.4 Basalt Fiber Geogrid

Basalt fiber geogrid is made primarily from basalt fiber roving through weaving and surface treatment. It offers advantages such as high resistance to fatigue cracking, high-temperature rutting, and low-temperature shrinkage cracking, along with excellent compatibility with asphalt mixtures.

Applying basalt fiber geogrid can resist excessive pavement deformation and effectively delay and reduce reflective cracking. It can be used for subgrade reinforcement and pavement strengthening in asphalt and cement roads, crack prevention at joints between old and new pavements during road widening and reconstruction, crack prevention in overlays on old cement and asphalt concrete pavements, and as heating grids for snow/ice melting on roads and airport runways.