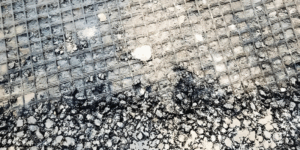

In the field of modern civil engineering materials, basalt fiber geogrid, a reinforcement material made from natural basalt, is gaining increasing attention. Made from volcanic basalt, it is melted at high temperatures and then processed through processes such as drawing, weaving, and coating to form a grid-like geosynthetic material. This material is primarily used in engineering to strengthen soil structure, distribute loads, and inhibit crack propagation. Its performance characteristics differ from those of traditional metal or polymer grids.

1.Material properties

Through high-temperature melting and drawing processes, basalt is transformed into continuous fibers, which are then woven into a mesh structure. This material exhibits high tensile strength and modulus, as well as good corrosion resistance and stability in acidic and alkaline environments. It also has good temperature resistance, adapting to a wide range of environments, from low to high temperatures.

2. Application areas

Basalt fiber geogrids are primarily used in civil engineering and infrastructure construction. In highway and railway projects, they can be used to reinforce roadbeds, improve the bearing capacity and durability of pavement, and reduce cracking and settlement. In water conservancy projects, they can be used to reinforce embankments and riverbanks to prevent soil erosion. In slope protection and land reclamation projects, these geogrids can also stabilize soil.

3. Advantage Analysis

The advantages of basalt fiber geogrids primarily lie in their material properties and environmental adaptability. Its high tensile strength effectively distributes loads and extends the life of the project. Its corrosion resistance makes it more durable in humid or chemical environments, reducing maintenance requirements.

4. Development prospects

With advances in engineering materials technology, the application of basalt fiber geogrids is expected to expand further in the future. In areas like Zhejiang, demand for this high-performance, environmentally friendly material is expected to grow with the continued development of infrastructure. Research directions may include optimizing production processes to increase efficiency or developing composite geogrids for enhanced versatility. Improvements in industry standards and quality control systems will help enhance product reliability and applicability.