High-performance fibers refer to a type of special fiber that exhibits exceptional resistance to physical and chemical effects from the external environment.

They are one of the main development directions in the chemical fiber industry in recent years. Based on chemical composition, they can be divided into organic high-performance fibers and inorganic high-performance fibers.

High-performance fibers are not only crucial strategic materials urgently needed for the development of the aerospace and defense industries, but they also play an irreplaceable role in advancing various strategic emerging industries, low-carbon economy, energy conservation, and emission reduction.

They are one of the indicators reflecting a country’s comprehensive strength and technological innovation. Japan, the United States, and developed European countries attach great importance to and have long monopolized the global research and development, production, and market of high-performance fibers.

Since 2006, with key support from national policies and finances, China’s high-performance fiber industry has developed rapidly, establishing a relatively complete system for the research and development of domestic high-performance fiber preparation technologies, engineering practices, and industrial systems.

This has significantly narrowed the gap with developed countries and effectively alleviated the urgent demand for high-performance fibers in the national economy and defense construction. The following introduces common high-performance fibers.

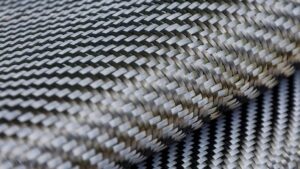

Carbon fiber is a fibrous material with a carbon content of over 90%. It possesses characteristics such as light weight, high strength, corrosion resistance, high modulus, low density, no creep, good electrical and thermal conductivity, resistance to ultra-high temperatures in non-oxidizing environments, and good fatigue resistance.

It is an important foundational material for developing high-tech industries such as aerospace, new energy, and high-end equipment manufacturing. It is also an essential key material for manufacturing rockets, missiles, fighter jets, naval vessels, and various advanced military weapons, holding an irreplaceable strategic position in the defense and military sector.

Relevant data shows that currently, carbon fiber composites account for 30% to 40% of the usage in military aircraft and 15% to 50% in large passenger aircraft. For example, the usage of carbon fiber composites in the U.S. F-22 and F-35 fighter jets reaches 24% and 36% respectively, the B-2 stealth strategic bomber exceeds 50%, the U.S. “Global Hawk” unmanned reconnaissance aircraft reaches 65%, and the “Raytheon” unmanned aircraft even exceeds 90%.

At the same time, in the civil aviation sector, the usage of composite materials in large passenger aircraft such as the B-787 and A-380 has exceeded 50%. China’s military aircraft, domestic large aircraft, satellites, spacecraft, etc., have also begun to use carbon fiber composites, but the application proportion and level are far lower than those abroad.

Among them, the usage of carbon fiber and composites in third-generation fighter jets is less than 5%, and although the usage in fourth-generation fighter jets has increased, it still has not reached 20%. The usage of carbon fiber composites in domestic large aircraft is less than 15%, and all are imported. In 2020, the global demand for carbon fiber was 10.6 kilotons.

The operating capacity of carbon fiber in mainland China was approximately 3.6 kilotons, with an actual production of about 1.8 kilotons, ranking second in the world.