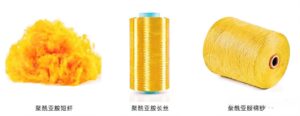

What is polyimide fiber

Polyimide fiber, also known as aromatic imide fiber, is one of the most comprehensive organic polymer fibers. Along with carbon fiber and aramid fiber, it is considered one of the three key polymer materials that hinder the development of my country’s high-tech industries. Due to its excellent mechanical strength, electrical insulation, and thermal stability, it is widely used in aerospace, military, automotive, electronics/electrical, and textile and apparel industries.

Excellent functional characteristics:

1. High and low temperature resistance

The molecular chain of polyimide fiber has excellent cross-linking effect, can form a tight structure, effectively block the transfer of heat, and has excellent high and low temperature resistance.

2. Flame retardant properties

It has self-extinguishing properties, that is, once you leave the fire source, the flame will go out quickly and will not easily reignite.

3. Radiation resistance

Its performance remains stable after being exposed to high-energy radiation.

4. High insulation performance

It has good electrical insulation properties, its dielectric constant is low and remains stable over a large range.

5. Corrosion resistance

It has excellent corrosion resistance to a variety of chemical reagents, such as acids, alkalis, organic solvents, etc.

6. High strength and high modulus

It has the characteristics of high strength and high modulus, with the maximum strength reaching 5.86.3GPa and the maximum modulus reaching 280340GPa.

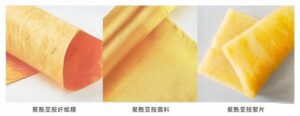

7. Good spinnability and dimensional stability

It has good spinnability and can be easily spun into fiber products of various specifications.

8. Low water absorption and unique cross-sectional structure

Polyimide fibers have low water absorption, which allows them to maintain good performance in humid environments.

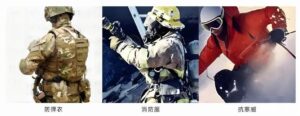

Wide range of applications

High-temperature protection: High-temperature flame-retardant protective clothing, parachutes, and honeycomb structural materials.

Electrical insulation: Motor winding insulation and printed circuit boards.

Composite reinforcement: Aerospace structural components and high-temperature dust filtration materials.

In summary, the application areas of polyimide fiber range from tough ropes for deep-sea exploration to thermal insulation equipment for polar scientific expeditions, from tiny components for precision electronics to lightweight materials for new energy vehicles. Polyimide fiber will shine even brighter with its unique charm.