Quartz fiber is a key strategic material in the aerospace manufacturing field.

The current rapid development of the low-altitude economy is expected to drive strong demand for quartz wool.

Possesses high-temperature resistance, ablation resistance, and excellent wave transmission and electrical insulation properties.

It is widely used in reinforcing critical structures of aircraft to achieve wave transmission and thermal insulation, making it a preferred material for wave-transparent structural components in aerospace vehicles.

Materials are used in passive and semi-active thermal protection structures, and have been widely used in the manufacture of ceramic thermal insulation tiles and flexible thermal insulation felts to provide critical thermal protection in harsh flight environments.

Quartz Material Industry Overview

This is an inorganic non-metallic fiber, made from high-purity silicon dioxide or natural quartz through a special process.

Its manufacturing process differs from other fibers, typically employing a high-temperature melting and drawing method to produce filaments from natural quartz.

These filaments, drawn from high-purity silica or natural quartz crystals after high-temperature melting, can be further processed into various forms such as quartz yarn yarn, felt, and chopped strands.

In high-frequency and operating environments below 700°C, quartz fiber maintains a stable and extremely low dielectric constant and loss, making it an ideal material for critical aerospace components.

Can be used not only as a reinforcement in high-temperature ablation-resistant materials for manufacturing important aircraft components such as tail fins, struts, nozzles and exhaust pipes, but also in ablation-resistant materials for reentry vehicles and propulsion insulation.

Applications in the aerospace field:

Due to its excellent wave transmission and heat insulation properties, quartz fiber plays an important role in missile seeker radar domes and heat shield systems.

Furthermore, products such as quartz wool and quartz felt are widely used in semiconductor high-temperature furnaces and automotive glass tempering furnaces.

When silica fiber is combined with prepreg, it can be processed to produce high-performance reinforced composite materials.

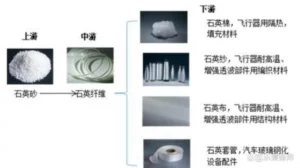

Quartz Fiber Industry Chain Overview:

The main upstream raw materials include high-purity quartz sand and graphite products;

The prices of these raw materials directly affect the cost structure of the entire industry.

Downstream products are mainly quartz fiber reinforced composite materials, applied in the aforementioned end-use fields.

The preparation process of quartz fiber includes mineral processing, grinding, and purifying natural crystals to form quartz powder.

The quartz powder is then processed into fused quartz rods, which are then melted to produce quartz fiber filaments and quartz wool.

Through refined weaving processes, silica fiber filaments are woven into more than ten types of quartz glass fiber products, including quartz yarn, quartz cloth, and quartz sleeves.

Quartz fiber Industry Chain Diagram: