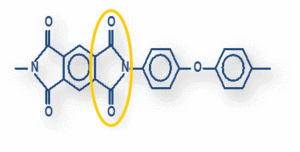

Polyimide refers to a polymer containing an amide structure in its main molecular chain. Polyimides are a very large family of polymers, and the backbone of high-performance polyimides (PIs) is primarily composed of aromatic and heterocyclic rings.

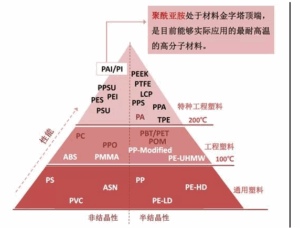

PI boasts the highest flame retardancy rating (UL-94), excellent electrical insulation, mechanical properties, chemical stability, aging resistance, radiation resistance, and low dielectric loss. These properties do not significantly change over a wide temperature range (-269°C to 400°C). It is hailed as “one of the most promising engineering plastics of the 21st century” and a “problem solver.” It can be said that “without polyimide, there would be no microelectronics today.” Its performance is at the pinnacle of the polymer material pyramid.

1. Research status of polyimide fiber

Polyimide fibers were first introduced in the 1960s, but high production costs and underdeveloped technology at the time limited their development. It wasn’t until the end of the 20th century, with advances in synthesis and spinning techniques, and the needs of certain specialized fields, that researchers actively engaged in polyimide fiber research. The high performance of polyimide makes its research of great value.

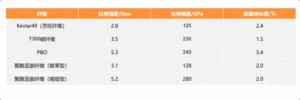

Polyimide fiber is one of the most heat-resistant organic synthetic fibers currently available. It can be used as a flame-retardant alternative to aramid in industrial applications. Compared to aramid and polyphenylene sulfide fibers, polyimide fiber surpasses them in terms of light resistance, water absorption, and heat resistance.

Due to its excellent heat resistance and mechanical properties, polyimide fiber is a core component material in key military applications such as aerospace and military aircraft. In the commercial sector, polyimide fiber is currently in its early stages of development in applications such as environmentally friendly filter materials and fireproofing materials.

2. Preparation of polyimide fiber

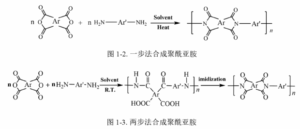

After decades of research, polyimide synthesis can be categorized into two methods, one-step and two-step, based on the number of steps required.

The one-step method involves heating two monomers, diamine and dianhydride, to the desired temperature of 150-250°C in a specific high-boiling-point phenolic solvent to directly produce polyimide.

The two-step method involves treating the two monomers, diamine and dianhydride, in an aprotic polar solvent, allowing the solution to undergo low-temperature polycondensation to produce a polyamic acid solution. This solution is then desolvated and subjected to a high-temperature cyclization treatment to produce the polyimide.

3. Application of polyimide fiber

(1) Environmental protection: Polyimide fiber is a typical application in the environmental protection field as a high-temperature dust removal filter material. Since polyimide fiber can be spun to form a very high surface volume coefficient, it provides conditions for capturing dust particles and improves dust particle filtration efficiency. In addition, polyimide has excellent heat resistance, making it the best high-temperature filter material currently.

(2) Reinforcement and protection fields: Polyimide fibers are widely used in the nuclear energy industry, aerospace, national defense and military industries due to their excellent physical and chemical properties such as high strength and modulus, corrosion resistance, high temperature resistance and flame retardancy. In the aerospace field, polyimide fibers can be used to manufacture lightweight cable sheaths for spacecraft.

(3) Textile and clothing field: Polyimide fiber has excellent properties such as thermal insulation. In recent years, it has been extended from the special protection field to the civilian textile and clothing field.